We have been in the production-end of the lumber business for several decades, building entire planning mills, large sawmill additions, and, of course coating plants. Although there are several good outfits that fabricate coating components, the thing that sets us apart is our decades of actual operation of these various production facilities. We gradually started tweaking the ill-designed, light weight components, for our own in-house use. From this incremental process, we were soon building our own heavy stainless equipment. People within the industry started asking us if we’d build one for them too, and you know the rest of the story.

Consulting

More than just a custom lumber equipment fabricator; PLSC specializes in start-to-finish turnkey solutions for your plant or mill. Contact us today for a free consultation.Fabrication

PLSC provides only the finest custom built equipment; tailored for your individual needs. We employ expert fabricators to build best-in-class solutions that produce results.Experience

With over a century of combined experience in the Lumber Services Industry, you can trust PLSC to deliver the finest equipment and solutions right to your door.Contact Us For More Information

We are happy to discuss how PLSC Solutions can help you on your next project.

Visit Us On YouTube

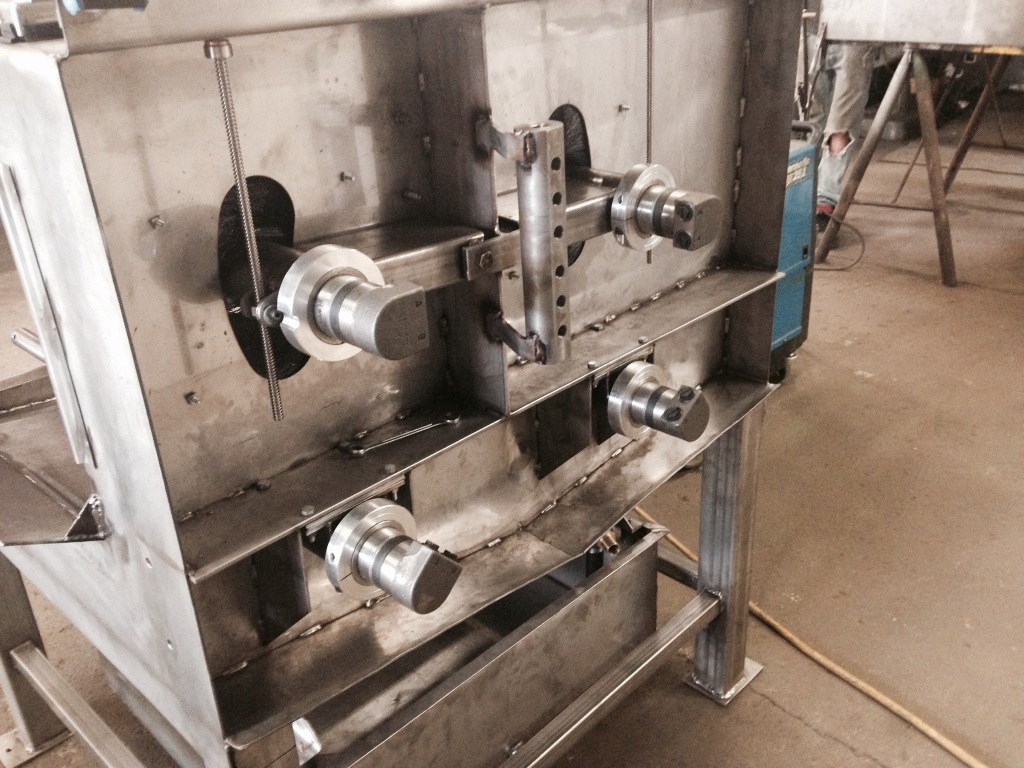

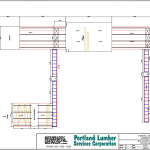

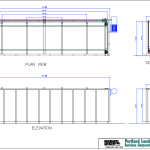

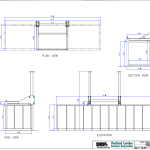

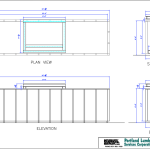

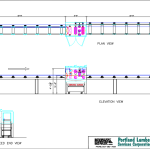

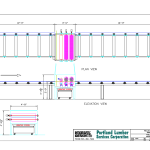

We specialize in the design, fabrication, installation, and start-up of both spray coating , and flood coating designs. Products range from high speed (up to 3,000 fpm) coaters, installed in conjunction with sawmill and planning mill equipment, to slower (250-500 fpm) “free standing” lines for the application of primers, and topical fire retardants.

- Heavy stainless steel construction throughout

- Custom designed in-feed and out-feed transfer systems

- Convection ovens (both transverse and linear orientation)

- In-line sanders

- Auto stackers

From the time an inquiry comes to us, from a chemical company, a paint manufacturer, or the end user, we work up a rough idea of the scope of the project.When possible, we will furnish a preliminary proposal. Next will be an on-site inspection, followed by a formal proposal, with drawings and much detail, both about the equipment, and also about the projected line speed, and paint usage / direct labor estimates.

After fabrication is complete, we will be on-hand to help with start-up; both health and safety training, and production training. When we leave, we expect that the line will be running well. To date, we have never left a plant site where there are unresolved problems related to our project.

After sale; parts availability, and continuing support are provided.

In cases where the installation is an involved operation, we can negotiate a separate installation deal, with a millwright crew.

Many of these lines are shipped in pre-wired, pre-plumbed segments, with very little on-site work involved.